15.8 Product Development

[Author removed at request of original publisher], Published by University of Minnesota

Like PowerSki, every organization—whether it produces goods or provides services—sees Job 1 as furnishing customers with quality products. The success of a business depends on its ability to identify the unmet needs of consumers and to develop products that meet those needs at a low cost (Ulrich & Eppinger, 2000). In other words, effective product development results in goods and services that can be sold at a profit. In addition, it results in high-quality products that not only satisfy consumer needs but also can be developed in a timely, cost-efficient manner. Accomplishing these goals entails a collaborative effort by individuals from all areas of an organization: operations management (including representatives from engineering, design, and manufacturing), marketing, accounting, and finance. In fact, companies increasingly assign representatives from various functional areas who work together as a project team throughout the product development processes. This approach allows individuals with varied backgrounds and experience to provide input as the product is being developed.

Product Development Is a Risky Proposition

Not surprisingly, developing profitable products is difficult, and the success rate is low. On average, for every successful product, a company has twelve failures. At this rate, the firms on the Fortune 1000 list waste over $60 billion a year in research and development (Ulwick & Eisenhauer, 2006). There are several reasons why product development is such a risky proposition:

- Trade-offs. You might, for instance, be able to make your jogging shoes lighter than your competitors’, but if you do, they probably won’t wear as well. They could be of higher quality, but that will make them more costly (they might price themselves out of the market).

- Time pressure. Developing a product can require hundreds of decisions that must be made quickly and with imperfect information.

- Economics. Because developing a product requires a lot of time and money, there’s always pressure to make sure that the project not only results in a successful product but also gets it to market at the most opportune time. Failure to be first to market with an otherwise desirable new product can cost a company a great deal of money.

Even so, organizations continue to dedicate immense resources to developing new products. Your supermarket, for example, can choose from about one hundred thousand items to carry on its shelves—including twenty thousand new products every year. Unfortunately, the typical supermarket can stock only thirty thousand products (Hannaford, 2006).

The Product Development Process

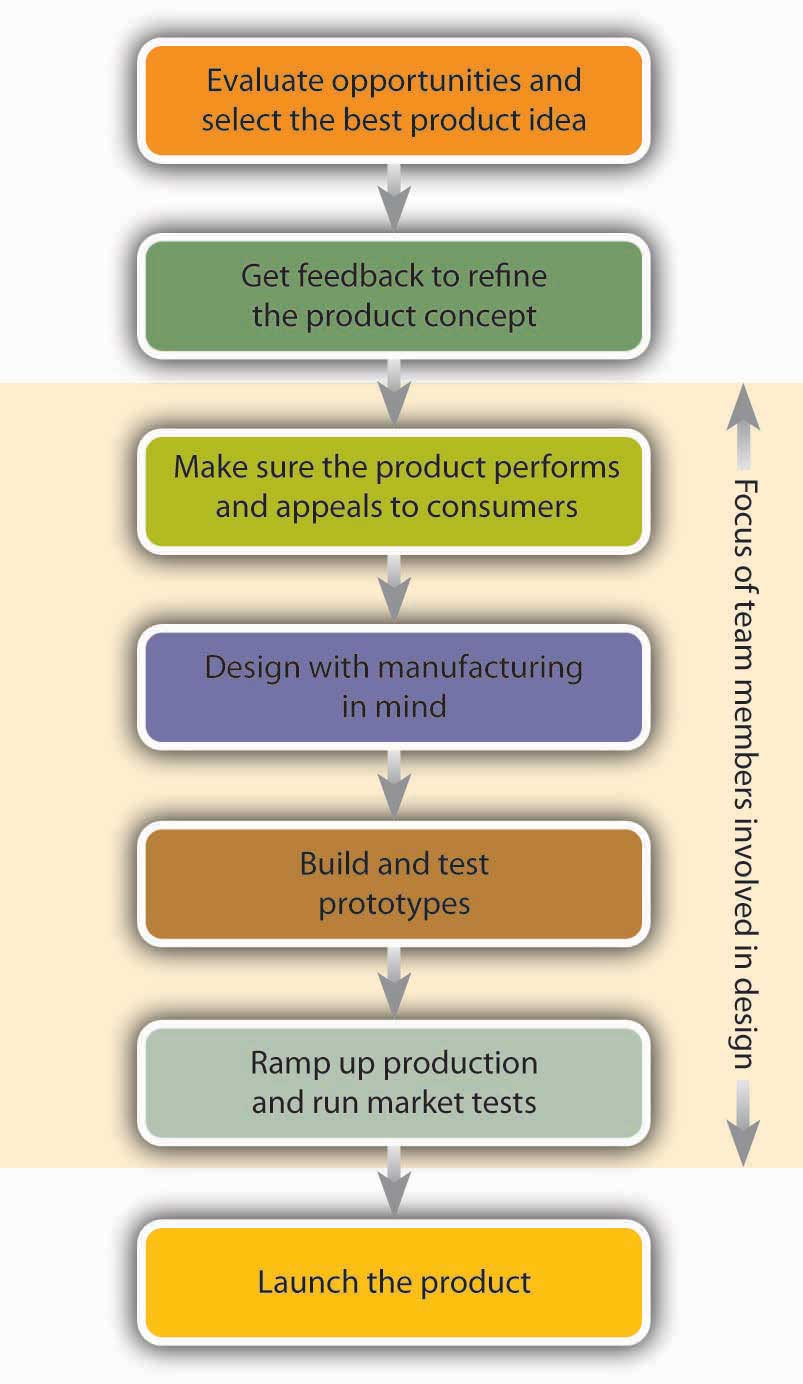

The product development process is a series of activities by which a product idea is transformed into a final product. It can be broken down into the seven steps summarized in Figure 15.6: The Product Development Process.

Evaluate Opportunities and Select the Best Product Idea

If you’re starting your first business, you might have only one product idea. But existing organizations often have several ideas for new products, as well as improvements to existing ones. Where do they come from? They can come from individuals within the organization or from outside sources, such as customers. Typically, various ideas are reviewed and evaluated by a team of individuals, who identify the most promising ideas for development. They may rely on a variety of criteria: Does the proposed product fill an unmet need of our customers? Will enough people buy our product to make it commercially successful? Do we have the resources and expertise to make it?

Get Feedback to Refine the Product Concept

From the selected product idea, the team generates an initial product concept that describes what the product might look like and how it might work. Members talk both with other people in the organization and with potential buyers to identify customer needs and the benefits that consumers will get from the product. They study the industry in which the product will be sold and investigate competing products. They brainstorm various product designs—that is, the specifications for how the product is to be made, what it’s to look like, and what performance standards it’s to meet.

Based on information gathered through this process, the team will revise the product concept, probably pinpointing several alternative models. Then they’ll go back to potential customers and get their feedback on both the basic concept and the various alternatives. Based on this feedback, the team will decide what the product will look like, how it will work, and what features it will have.

Make Sure the Product Performs and Appeals to Consumers

The team then decides how the product will be made, what components it will require, and how it will be assembled. It will decide whether the product should be made in-house or outsourced to other companies. For products to be made in-house, the team determines where parts will be obtained. During this phase, team members are involved in design work to ensure that the product will be appealing, safe, and easy to use and maintain.

Design with Manufacturing in Mind

As a rule, there’s more than one way to make any product, and some methods are more expensive than others. During the next phase, therefore, the team focuses its attention on making a high-quality product at the lowest possible cost, working to minimize the number of parts and simplify the components. The goal is to build both quality and efficiency into the manufacturing process.

Build and Test Prototypes

A prototype is a physical model of the product. In the next phase, prototypes are produced and tested to make sure that the product meets the customer needs that it’s supposed to. The team usually begins with a preliminary prototype from which, based on feedback from potential customers, a more sophisticated model will then be developed. The process of building and testing prototypes will continue until the team feels comfortable that it has fashioned the best possible product. The final prototype will be extensively tested by customers to identify any changes that need to be made before the finished product is introduced.

Ramp Up Production and Run Market Tests

During the production ramp-up stage, employees are trained in manufacturing and assembly processes. Products turned out during this phase are carefully inspected for residual flaws. Samples are often demonstrated or given to potential customers for testing and feedback.

Launch the Product

In the final stage, the firm starts ongoing production and makes the product available for widespread distribution.

Key Takeaways

- The success of a business depends on its ability to identify the unmet needs of consumers and to develop products that meet those needs at a reasonable cost.

- Accomplishing these goals requires a collaborative effort by individuals from all areas of the organization: operations management (including representatives from engineering, design, and manufacturing), marketing, accounting, and finance.

- Representatives from these various functional areas often work together as project teams throughout the product development process, which consists of a series of activities that transform a product idea into a final product.

-

This process can be broken down into seven steps:

- Evaluate opportunities and select the best product mix

- Get feedback to refine the product concept that describes what the product might look like and how it might work

- Make sure that the product performs and appeals to consumers

- Design with manufacturing in mind to build both quality and efficiency into the manufacturing process

- Build and test prototypes, or physical models of the product

- Run market tests and enter the ramp-up stage during which employees are trained in the production process

- Launch the product

Exercise

Use your imagination to come up with a hypothetical product idea. Now, identify the steps you’d take to design, develop, and bring your product to market.

References

Hannaford, S., “Slotting Fees and Oligopolies,” http://www.oligopolywatch.com/2003/05/08.html (accessed May 11, 2006).

Ulrich, K., and Steven Eppinger, Product Design and Development, 2nd ed. (New York: Irwin McGraw-Hill, 2000), 3.

Ulwick, T., and John A. Eisenhauer, “Predicting the Success or Failure of a New Product Concept,” The Management Roundtable,http://www.roundtable.com/Event_Center/I@WS/I@WS_paper3.html (accessed May 11, 2006).

when companies assign representatives from various functional areas who work together

series of activities by which a product idea is transformed into a final product

describes what the product might look like and how it might work

is a physical model of the product

Products turned out during this phase are carefully inspected for residual flaws